Sources on the Thingiverse

The big heights in the house looks great, but it has a dark side. The spiders in the upper corners. It is not easy to remove spider nets from 5m height. Either you need a big expandable ladder (what I hate) or something expand your arm to such length.

I chosen the second option.

Bought three 2m length aluminum pipes, 30, 25 and 20mm diameter, and designed this:

Printed it in four versions. Two pieces in one set:

Assembled (one set: eight M4x45 screws, eight M4 nuts, one M6 nut, one M6x15 thumbscrew):

How does it look like when expanded:

Let's tremble spiders! I'm coming!

2017. december 25., hétfő

2017. december 19., kedd

Printing for my Lab 2. - Hammer holders

Continued to populate my pegboards. Now I made something for my hammers:

Printed and assembled:

Hammers mounted:

Printed and assembled:

Hammers mounted:

2017. december 12., kedd

Printing for my Lab

After a long time (I think around 3 years) I decided to reanimate my CNC Router.

As first thing I cleaned the mess on its top (mainly the new stepper drivers, elastic couplers, drill and mill bits was there). I wanted to have final place for those drill/mill bits. So I printed holders for it, what can fit on the tool holder board:

Designed:

Printed:

In work:

As first thing I cleaned the mess on its top (mainly the new stepper drivers, elastic couplers, drill and mill bits was there). I wanted to have final place for those drill/mill bits. So I printed holders for it, what can fit on the tool holder board:

Designed:

In work:

2017. december 10., vasárnap

High Voltage DC Power Supply 4. - The phase switching module

!!!DANGER!!!

The circuit described bellow is dangerous. Using it improperly will kill you. On the other side I may also made mistakes during the design and built. I'll take absolutely no responsibility for it. If you want to build it, please don't ask for circuit board or help. I won't help you.

In my previous posts about the high voltage supply I already wrote about the small electronics able to keep the GND of the DC side on earth potential without isolation.

No this is not voodoo. It just a simple circuit.

The theory:

The protective earth connection in the mains connector is connected to the mains null somewhere in your system. Probably somewhere around the utility meter. So if we measure the voltage between the Line and Earth, it will be the full mains voltage. If we measure the voltage between the Null and the Earth, it will be zero. To be able to work with, I draw the following circuit:

This is just two simple zener regulator, what provide the necessary sense signals for the further processing.

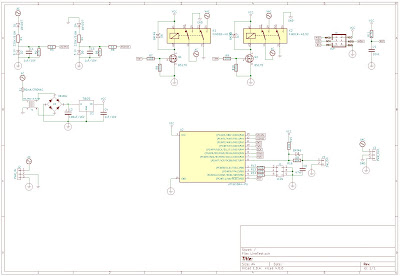

I designed a complete circuit around this, with an MCU, a 5V power supply, MOSFETs for driving relays and two DPDT relay.

The board design:

Based on this design I ordered the boards from allpcb. Actually I made a mistake around the design. I bought my relays after I sent the board for manufacturing. The result is that I connected the switched circuit on wrong direction. This means if I build the circuit the relays create a short circuit to the mains.

Throw away the boards (without even soldering a single component), ordered a new batch.

It also arrived within a few days:

The finished board:

I wrote a small arduino code to run the board. It has an ATTINY84 in it. Actually the code would fit in an ATTINY24 easily.

Assembled the whole thing into it's final place:

I connected the final thing to the mains. Switched on the power switch. Everything looked fine, until I pressed the output button.

The main circuit breaker in my house went off. Shitt.

Few more tries. The result get even worst. It killed the mains even switching on the power switch and not the output button.

Removed the phase switching board. Measured. It looked like both of the relays killed. There was a short circuit between the line and the neutral on the board.

Here is when Murphy comes into the picture. How many components buy I usually for my circuits? Way more than needed. Except this case. I had only those two relays on the board. Weekend. I should wait until Monday, to replace the relays.

In the meantime I removed the relays from the board - I hate the THT desoldering.

Removed the cap from one of the relays to be able to make a picture of the burnt contacts:

The surprise come here. No burned contact. Even I made a picture with my microscope. The result is the same:

Nothing, the contacts are intact. Measured the second desoldered relay, what still has it's cap. the result is the same, no sign of the failure anymore.

Just my guess that the heat and mechanical torture of removing the relays of the board resolved the temporal latch-up of the contacts.

Now back to the basics. As I can't find out the source of the problem (didn't wanted to play this game with new relays). I just guessed that the inrush current of the capacitors causing the problem (as I wrote earlier, I had problem with it already). So I hacked a solution. Together with the new relays I bought some inrush protector NTCs. It isn't an ideal solution, but hopefully will be sufficient. Hacked a PDU board to accommodate the NTCs. I've a few spare anyways:

The relays replaced. The whole thing works as expected.

I'm still thinking about the proper solution. The device is a tool and not a target for me. So it may not worth the effort to build a second version.

2017. december 4., hétfő

Conrad Energy Logger

I'm quite unhappy.

Yesterday I checked the thermostat I built for the dog house. I felt that is maybe some problem with it. So I wanted to check the power consumption. If it is between 30-40W means everything in order.

Here is the result:

Well done Conrad

Congratulations for this extremely reliable, stable product.

Yesterday I checked the thermostat I built for the dog house. I felt that is maybe some problem with it. So I wanted to check the power consumption. If it is between 30-40W means everything in order.

Here is the result:

Well done Conrad

Congratulations for this extremely reliable, stable product.

2017. december 1., péntek

2017. november 28., kedd

High Voltage DC Power Supply 3.

!!!DANGER!!!

The circuit described bellow is dangerous. Using it improperly will kill you. On the other side I may also made mistakes during the design and built. I'll take absolutely no responsibility for it. If you want to build it, please don't ask for circuit board or help. I won't help you.

So, I continued to work on the issues from the previous post.

"Mill a hole for the mains socket and the circuit breaker to the backpanel"

done

"Mill the holes for the banana jacks to the front panel"

Actually it was much simpler than I meant originally. My step drills eventually arrived. Sooner than expected. Never used such tool previously. On the first try I was able to drill the holes in no time.

"Finish the wiring"

done

"Set the correct decimal dots"

It wasn't easy to remove those solder blobs, but done

"build a dummy load to be able to test the current measurement"

Actually a professional DC electronic load what is able to work above 300V isn't cheap. So I decided to pick a 100W 1K resistor and screwed onto an old s478 heathsink. The question is if the fan have to be used. Finally it worked without it.

"Calibrate"

done

"Paint the front panel"

done

Actually I had serious problem with assembling the panel meters into the front panel. Most of the fixing clamps are broken of (because of the material aging or bad construction, who knows)

I hate that hot snore glue, but I had no other option here, to keep the panel meters in its place:

"Build the phase switching electronics (not mandatory, maybe after finish)"

Actually I've quite a progress with it, but it will be the subject of an other post. Not finished yet, so it is not assembled into the unit yet.

"Create the console for the caps"

This was funny. I don't know why I completely forgot that the outside (and therefore of the mounting screw also) of those large cans are the negative pole of the capacitor. building two caps with different potential on the same conductive (aluminum) mount is not a best idea of the world:

Luckily I realized this before switching on, and exchanged the mounting plate to a plastic one (unused etched FR4):

As I'm at the end of the todo points. The project is almost finished (just the phase switching electronics missing):

What's next:

I'll finish the phase switching electronics and install it.

The PSU itself has some room for improvement. Like cold start current limiting and proper capacitor draining. I'm not quite sure, that those improvements will be done in the near future. The usability of the equipment will tell.

2017. november 14., kedd

High Voltage DC Power Supply 2.

!!!DANGER!!!

The circuit described bellow is dangerous. Using it improperly will kill you. On the other side I may also made mistakes during the design and built. I'll take absolutely no responsibility for it. If you want to build it, please don't ask for circuit board or help. I won't help you.

As the other PCBs are arrived for the supply, I continued the build.

Finished the separated isolated supplies for the panel meters (these are nothing else just a simple dual 7809 based linear supplies):

Also added the power distributor and some wiring for the backpanel:

Connected the panel meters and, milled parts of the front panel (manually as my CNC mill is still broken)

How the whole thing looks like today:

How the whole thing looks like today:

And its working, partially:

As you see the decimal dot is on the bad place (it is more likely 330V than 33V)

In addition I took a picture of the board on thermal camera. You can clearly see that the two capacitor draining resistors getting warm:

In addition I took a picture of the board on thermal camera. You can clearly see that the two capacitor draining resistors getting warm:

So I can tell, it is progressing, but quite few things still ahead of me:

- Mill a hole for the mains socket and the circuit breaker to the backpanel

- Mill the holes for the banana jacks to the front panel

- Finish the wiring

- Set the correct decimal dots

- build a dummy load to be able to test the current measurement

- Calibrate

- Paint the front panel

- Build the phase switching electronics (not mandatory, maybe after finish)

- Create the console for the caps

continue...

2017. november 11., szombat

PCB manufacturing

Quite a few of my new designs are ready. Arrived during the last week.

Just find time to build, test and write about them:

Just find time to build, test and write about them:

2017. november 4., szombat

High Voltage DC Power Supply 1.

!!!DANGER!!!

The circuit described bellow is dangerous. Using it improperly will kill you. On the other side I may also made mistakes during the design and built. I'll take absolutely no responsibility for it. If you want to build it, please don't ask for circuit board or help. I won't help you.

I've many ideas in my had, what to build, what to experiment with.

A few of them involve using mains voltage directly. Some of this need to rectify and clean the input before using.

My lab power supplies are able to produce 60V DC maximum, what is clearly not enough for those experiments. A cost of a proper high voltage variable DC supply is enormous, and I don't need most of the features of it right now:

- Not need to be variable. My built circuits will have rectifications on its own. The input comes from mains anyways so this is the only voltage I need.

- Not need to be stabilized. Same concept as above.

- Not need to be isolated. I know, at this point the real professionals start to scream: IDIOT!!!! Let me explain why I'm not:

1. I've built a proper isolation transformer in the past. I can use it, when it is necessary.

2. My negligence: two way rectified mains after filtering in my country is around 650V DC. It is lethal anyways. If you make a mistake, it will kill you. It can't kill you twice because of the missing isolation.

So the plan:

Build a simple two way rectified supply with large can electrolytic capacitors (I bought 3300uF/500V ones for a good price. These puppies are huge).

Add necessary circuits for small panel meters to be able to measure, what is coming out from the circuit.

Add necessary circuit to discharge the capacitors. If they left unattended, they can still kill you after long time.

Add a special circuit I designed for it. It has two functions:

- Test if the equipment grounded to the protective earth (it is not a proper grounding test, but if your lab is properly grounded, it will tell you if you have cabling problems)

- Test the polarity of the incoming supply and change it if necessary. So the 0V output line of the equipment is always connected to the Null and never to the Line.

This circuit is still under development, so I don't know if it will work or not, but it isn't absolutely necessary for my power supply design. It adds some protection to the circuit, but nothing substitute the extreme care and the proper isolation.

I started to design this something like two weeks ago. Ordered the circuit board on the last Saturday. Actually it is already in my hands since Thursday, thanks to the extremely cheap, fast and high quality PCB manufacturer I found recently: ALLPCB (10 pcs 100x100 two sided boards for $5.49 delivered in 5-6 days - insane):

Yesterday I had some time to populate the board:

Those cans are huge, I told you.

Let see some measurement:

I've an isolation transformer, as I told before.

Ouch! My Fluke 117 unable to measure the output voltage. According to the specification it is able to measure until 600V. In fact it was working until 650V, but the supply is above this. Lets change to a 1000V rated tool:

So, the PSU works now. My first impression, that the 100k/5W resistors I connected in parallel with the capacitors are improper for draining them. It take quite a long time (several minutes) to do their job, and generating some (not to much) heat during the operation (the 3W consumption on the display of the isolation transformer). It is sufficient now, but I'm thinking to replace them to some active solution. (an AC Relay with some lower value/higher power resistors maybe).

This is it for now. Next is building into the enclosure, adding and calibrating the panel meters.

2017. október 23., hétfő

StepTest 2.

Finally I finished my StepTest project.

Here is the proper schematic diagram:

The PCB design:

I ordered it from SeeedStudio, so the professionally made board is also in my hands:

The built electronics:

Actually the design is not as good as it can be. I rather like my things in enclosed boxes. Here it wasn't an option as I need to access to the current limiting potentiometer.

And finally in working:

Just additional video (it is made with the prototype on the breadboard), what this small circuit is usable for:

I've a better device in my mind, I may build it sometimes.

Here is the proper schematic diagram:

The PCB design:

I ordered it from SeeedStudio, so the professionally made board is also in my hands:

The built electronics:

Actually the design is not as good as it can be. I rather like my things in enclosed boxes. Here it wasn't an option as I need to access to the current limiting potentiometer.

And finally in working:

Just additional video (it is made with the prototype on the breadboard), what this small circuit is usable for:

I've a better device in my mind, I may build it sometimes.

Feliratkozás:

Bejegyzések (Atom)