I restarted to work with electronics around 15 years ago.

At the beginning I decided, not to use analog meters (except on audio amplifiers) anymore. Those are not precise, outdated, etc.

But the things are changing.

I started to working on a project, what done some weird things. I guess, with changing the load, the power voltage is dropping and disrupting the input measurement.

This is something, I will never see on a regular digital multimeter. I either can use some higher speed data acquisition and record the result on a graph, or use an analog multimeter and see the needle movement.

Actually I don't have none of the methods actively setup at my lab.

I decided to go to the easier way, and get an analog multimeter working.

I still have an old Russian meter from the soviet era, inherited from my grandfather (he were the person teaching me electronics, when I was six). This meter was lying on the ceiling, as I didn't use it.

This meter wasn't switch on let say 30+ years.

This can be seen on the batteries left in it:

At least, those doesn't cause to much damage. Just some minor corrosion.

Anyway. Those meters only use batteries for resistance measurement. For this, I'll definitely will use my digital meters. So no batteries going back to the case.

Opened it. Actually it had the original factory seal on one of the screws. It was never opened before.

It is in perfect condition internally.

Tested. It is spot on. So I'll keep it for my measurements, where analog has advantages.

This could be the end of the story. But as usual, the little devil in my mind started to chase something.

I like much more the bench instruments than the handheld ones.

Looked around on the eBay. But didn't find any subject with reasonable price and condition.

What would be the result, if I design something, with the current component possibilities.

I have quite a few Ganz 101DA-2 panel meter. I bought a few as new, a few others on a ham market.

Based on those meters, I may can produce something interesting.

First, I started to work with one of the panel meters.

These things are by design has 100uA full range. The ones I bought has internal shunts to 5 or 20mA. First I wanted to remove those.

This time I was much more careful.

Used my Digistant voltage standard as source (it is not calibrated, and a bit off, but it is perfect for a very low voltage source), a current and a voltage meter.

So the result for the full scale is 95uA and 22.22mV. This means two things to me:

The coil resistance is ~234 ohm, and I can drive meter to full scale with let say 25mV. So I can play with these values.

With a good low noise FET input opamp, I may can go down to uV range while keeping high input impedance (thinking about 100Mohm).

We will see the results.

As you see the original scale plate is white, with just the start and the end marks. It is made from 0.9mm aluminum. I need a scale, but I have no equipment to make it from aluminum and paint is accordingly.

In addition, it would be nice to have a mirror scale (why not, if you can).

The original case, even have place for the mirror

I was thinking to find a place, where somebody can cut the proper mirror to me with waterjet. Thinking it further, I decided, to design the mirror size, print it in 3D and use a self adhesive mirror foil on it.

Next is the scale itself. I was thinking, how can I create the scale. First printing on paper and laminating it was my idea. But this is not the best for the mirror scale, as the cutout would not be easily achievable.

Then came the idea. What if I design it in KiCAD and send it to a board house for manufacturing.

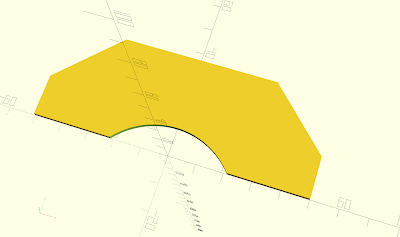

So the design born. The scale was designed in OpenSCAD, exported to DXF and used by KiCAD.

Here is the result:

As the board house create minimum 5 pcs, I'd like to figure out, what design to put to the other side. Then I'll send to manufacturing.

This is for now. I'll continue, as my build advance...

Nincsenek megjegyzések:

Megjegyzés küldése