As I have nothing more to do with the logic analyzer now (there is national holiday here in Hungary and I'll have other things to do on the next week, I've no chance to get a new quieter fan and work with it till 2nd November), I picked something waiting to me from the drawer.

I've around fifty of this. I've no PBX for this anymore, so it is useless except for some parts "harvesting".

First of all I disassembled one, and realized, that the only part can be useful is the display unit. I need to reverse engineer a little bit to find out, how can I drive it.

I was looking around but nothing found on the internet. No information, no service manual, no schematic design. In addition the display driver chip is the regular silicon mounted on the board type:

(how I hate these)

So, the first thing, to power it up somehow, because without the PBX, I not even know what kind of power source is needed. It was obvious for the first look that the main board contains a switching regulator:

I looked to the regulator IC, it wasn't familiar to me:

But I assumed that -5 mark means 5V. If I connect a little bit more than 5V to the +- pins of the rectifier bridge:

It will bring the unit alive. And around 8V:

The unit started.

To be continued...

2014. október 25., szombat

2014. október 22., szerda

Logic analyzer project 2. - first "repair"

After thinking a lot (2 sec) and reading thoroughly the service manual (5 min) with a long hard work (30 sec) I repaired the bigger fault of the Logic Analyzer. The soft key button error:

And the high tech advanced tool used for the repair:

You see correctly it is a cosmetic cotton pad (a dirty one).

Explanation:

The unit has touch screen. This called "soft keys". Because of the age of the unit it is not a capacitive or resistive touch screen but an optical grid created with infrared LEDs and phototransistors.

And the high tech advanced tool used for the repair:

You see correctly it is a cosmetic cotton pad (a dirty one).

Explanation:

The unit has touch screen. This called "soft keys". Because of the age of the unit it is not a capacitive or resistive touch screen but an optical grid created with infrared LEDs and phototransistors.

- When I first seen the error I think that one of the LEDs may failed (2 sec)

- Then I read the manual what the error code is about (5 min)

- When it proved that my theory is close to the possible cause, first cleared the frame of the display (30 sec)

Logic Analyzer project

I was crawling on eBay, and found an old Tektronix 1240 logic analyzer for a few bucks. The seller stated, it is defective because the picture intensity is weak on the screen (and it has defective soft buttons as it can be seen on the pictures).

I was thinking a little bit. This logic analyzer may not the best for today's digital electronics projects, but a good looking something what may deserve a restoration.

What if I replace the monitor with a same size LCD panel. So I took a bid on and bought it. Afterwards I found the service manual online. At a quick look in it found out that it produces an NTSC like TTL level signal for the display. I'm quite sure it is convertible to the current LCD screens.

After the bidding I was looking around the 7" LCD displays. Now I think it will be not so easy to do the conversion. Today's plan is the following:

Pick a low end FPGA (or a CPLD) attach some RAM to it. Read the signal into the RAM from the logic analyzer, and drive the LCD with the FPGA using the RAM as a frame buffer. (I can't do this in an MCU because the LCD panel needs 40MHz signaling)

To be honest, I've not even touched FPGA before ever, but this project could be a good one for learning. :-)

So I ordered an LCD and the necessary connectors and evaluating FPGA development boards.

After this introduction the Logic Analyzer arrived today.

I switched it on. And my colleague immediately found the contrast knob at the back side of the unit. So you can see here how week the display in reality:

As we see the todo changed:

- Repair the soft button problem

- Change the extremely noisy fan

I don't want to cancel my display change idea. I found that this series of logic analyzers has one bigger model: 1241. It has color display. What if I can "upgrade" mine to color one. If it is possible based on the Service Manual, I'll try. :-)

I was thinking a little bit. This logic analyzer may not the best for today's digital electronics projects, but a good looking something what may deserve a restoration.

What if I replace the monitor with a same size LCD panel. So I took a bid on and bought it. Afterwards I found the service manual online. At a quick look in it found out that it produces an NTSC like TTL level signal for the display. I'm quite sure it is convertible to the current LCD screens.

After the bidding I was looking around the 7" LCD displays. Now I think it will be not so easy to do the conversion. Today's plan is the following:

Pick a low end FPGA (or a CPLD) attach some RAM to it. Read the signal into the RAM from the logic analyzer, and drive the LCD with the FPGA using the RAM as a frame buffer. (I can't do this in an MCU because the LCD panel needs 40MHz signaling)

To be honest, I've not even touched FPGA before ever, but this project could be a good one for learning. :-)

So I ordered an LCD and the necessary connectors and evaluating FPGA development boards.

After this introduction the Logic Analyzer arrived today.

I switched it on. And my colleague immediately found the contrast knob at the back side of the unit. So you can see here how week the display in reality:

As we see the todo changed:

- Repair the soft button problem

- Change the extremely noisy fan

I don't want to cancel my display change idea. I found that this series of logic analyzers has one bigger model: 1241. It has color display. What if I can "upgrade" mine to color one. If it is possible based on the Service Manual, I'll try. :-)

2014. október 18., szombat

Multimeterless 4. - Uni-T, Philips

I've some more information about my Multimeter business. The problems with the Uni-T shipment finally got a resolution. I was waiting endlessly to the seller to resend them. A day before the resolution deadline from ebay, I sent one last message without answer, so I escalated the case to the ebay. The money arrived back, but no multimeters.

Because finally I've plenty of them on hand, I highly thinking about this Uni-T ones. I'm not sure if I still need them. The only problem that not all of them was ordered to me, so I should discuss with my friend what to do.

After a long journey my Philips PM2525 also arrived. It was a some mistake by the shipping company. It went to the Czech Republic instead of Hungary, and afterwords back to Germany. The seller seen some strange information in the online tracking, so asked me if it arrived. I told him, that I haven't received it. He called up the shipping company and after some rerouting the multimeter arrived.

As it here, As usual, I made some measurements with it:

DC Voltage:

It looks on spot

Resistance.

When I first tried it was a mess. I finally find out that the test lead I'm using is a crap. And the result:

It looks like it is on spot. Great meter.

Finally I tried to look inside. It is a definite failure:

I just have a bit type Torx screwdriver what doesn't fit into the hole deep in the stands of the meter and I don't want to destroy the screwheads - go shopping! :-)

Because finally I've plenty of them on hand, I highly thinking about this Uni-T ones. I'm not sure if I still need them. The only problem that not all of them was ordered to me, so I should discuss with my friend what to do.

After a long journey my Philips PM2525 also arrived. It was a some mistake by the shipping company. It went to the Czech Republic instead of Hungary, and afterwords back to Germany. The seller seen some strange information in the online tracking, so asked me if it arrived. I told him, that I haven't received it. He called up the shipping company and after some rerouting the multimeter arrived.

As it here, As usual, I made some measurements with it:

DC Voltage:

It looks on spot

Resistance.

When I first tried it was a mess. I finally find out that the test lead I'm using is a crap. And the result:

It looks like it is on spot. Great meter.

Finally I tried to look inside. It is a definite failure:

I just have a bit type Torx screwdriver what doesn't fit into the hole deep in the stands of the meter and I don't want to destroy the screwheads - go shopping! :-)

2014. október 14., kedd

POM #1 - Voltage inverter for breadboards 3.

The PCBs are arrived. I got 11 boards altogether what makes me possible to produce 44 inverters. The board quality is not worst than the ones created by seeedstudio's fusion service, and I got some nice stickers with the boards.

Thanks Ian!

I think this is not the last time I ordered from DirtyPCBs.

Thanks Ian!

I think this is not the last time I ordered from DirtyPCBs.

2014. október 9., csütörtök

Engineer joke - Continuance

Wednesday - Last week:

Today I dived deeper into the oscilloscope and it's service manual.

Now I know what the messages are mean:

CAN'T COMMUNICATE WITH UFO - I can't communicate with the front panel (handles)

WRONG AI HARDWARE VERSION - That AI is not AI but A1. I can't communicate with the analog board

NO ACKNOWLEDGE ON IIC - This evidently comes from the first two.

The construction of the unit is something like this:

There is a main board what is a passive backplane. The power supply and the processor board is plugged into this. A cable from the processor board goes to the analog unit and from the main board one to the front panel and one to the display electronics. From this the communication between the display and processor board is working.

The processor is not able to communicate with anything else. This points me to some I2C bus error. I tried out what happens if I disconnect the two cable of the error designated units one-by-one. This action doesn't eliminated the other board's error in any case. I presume based on this that I've a general problem with the I2C bus. Maybe the pullup is missing (the I2C is some kind of Open Collector bus, so not works without pullup resistors) or the clock generation has problems.

I think, I'll not solve this. So goes to a repair guy or back to the seller.

Friday:

I visited Mr. Urban (he is a famous shop owner/designer/repair guy here in Budapest). After looking to the unit, he said, he not take it, because it is a newer construction that he have knowledge on.Monday:

I still wanted a working unit. Asked the seller if I can send it back for repair and I pay both of the shipping charges.

He said that his technician is only able to use it but not able to repair it. So I've two options. I send it back and I get back my money(without the shipping costs), or I keep the unit and he sends back the half of the money. I chosen the later option.

Now I've two original probes (I had before only two Chinese crap and a half broken, repaired Philips), and a bad scope.

I take a deep breath and try to repair it. Most probably this effort will fail, but I'll learn a lot from it.Yesterday:

I've a little more chance. I found a processor board on the ebay, what together with the shipping charges cost less than the amount will be refunded from the scope. Now I just need to proof if this card is bad.

to be continued ... (when I start to repair it)

Today I dived deeper into the oscilloscope and it's service manual.

Now I know what the messages are mean:

CAN'T COMMUNICATE WITH UFO - I can't communicate with the front panel (handles)

WRONG AI HARDWARE VERSION - That AI is not AI but A1. I can't communicate with the analog board

NO ACKNOWLEDGE ON IIC - This evidently comes from the first two.

The construction of the unit is something like this:

There is a main board what is a passive backplane. The power supply and the processor board is plugged into this. A cable from the processor board goes to the analog unit and from the main board one to the front panel and one to the display electronics. From this the communication between the display and processor board is working.

The processor is not able to communicate with anything else. This points me to some I2C bus error. I tried out what happens if I disconnect the two cable of the error designated units one-by-one. This action doesn't eliminated the other board's error in any case. I presume based on this that I've a general problem with the I2C bus. Maybe the pullup is missing (the I2C is some kind of Open Collector bus, so not works without pullup resistors) or the clock generation has problems.

I think, I'll not solve this. So goes to a repair guy or back to the seller.

Friday:

I visited Mr. Urban (he is a famous shop owner/designer/repair guy here in Budapest). After looking to the unit, he said, he not take it, because it is a newer construction that he have knowledge on.Monday:

I still wanted a working unit. Asked the seller if I can send it back for repair and I pay both of the shipping charges.

He said that his technician is only able to use it but not able to repair it. So I've two options. I send it back and I get back my money(without the shipping costs), or I keep the unit and he sends back the half of the money. I chosen the later option.

Now I've two original probes (I had before only two Chinese crap and a half broken, repaired Philips), and a bad scope.

I take a deep breath and try to repair it. Most probably this effort will fail, but I'll learn a lot from it.Yesterday:

I've a little more chance. I found a processor board on the ebay, what together with the shipping charges cost less than the amount will be refunded from the scope. Now I just need to proof if this card is bad.

to be continued ... (when I start to repair it)

2014. október 3., péntek

Multimeterles 3. - Engineering Masterpiece

A multimeter arrived today. Now I've four of them, what is close to I'm expected on the beginning.

I wasn't aware of what is this thing when I was bidding on it on the ebay. But after it arrived I'm absolutely sure it worth every dime I payed for it. If I where in the place of Dave Jones, I would create a long YouTube teardown video with many "awesome" and "beauty" in it. But I'm not, so photos and some text coming.

After a such long introduction let see, what we talking about.

A Fluke 8500A 6.5 digit bench multimeter.

As you see this is not a unit manufactured today. To be honest, I don't know the exact manufacturing date, but the manual I found on the internet was created in 1977. This give us the hint that the unit is roughly 35 years old. 1977 you know, the year of Star Wars. :-)

It is coming from the ages when the products of the US companies was manufactured in the U.S.A.

The unit is heavy. It is around 10Kg. And in addition it was packed and sealed in the way in the box like it would survive even an atomic war.

When I switched on, it started immediately. I made some measurements against my references, together with my HP multimeter.

Voltage:

It is slightly off, so it will need some calibration if I'll use as a reference as I planed.

Resistance:

It looks on spot. By the way it would be nice to use the 4-wire resistance measurement, but I should buy some proper test leads (Kelvin clips) for it.

After the testing I opened the box (This was the second time. The first time was in the office with my colleague).

I was shocked. Never ever seen such order in any equipment (specially in something what is old like this). This looks like an engineering masterpiece.

Every single board is enclosed in a separate plastic cover. Every single board's plastic cover has a foldable door on the top of it, allowing access to calibration handles:

And finally a card with cover opened:

I'm really happy, that I'm the owner of this equipment now on.

I wasn't aware of what is this thing when I was bidding on it on the ebay. But after it arrived I'm absolutely sure it worth every dime I payed for it. If I where in the place of Dave Jones, I would create a long YouTube teardown video with many "awesome" and "beauty" in it. But I'm not, so photos and some text coming.

After a such long introduction let see, what we talking about.

A Fluke 8500A 6.5 digit bench multimeter.

As you see this is not a unit manufactured today. To be honest, I don't know the exact manufacturing date, but the manual I found on the internet was created in 1977. This give us the hint that the unit is roughly 35 years old. 1977 you know, the year of Star Wars. :-)

It is coming from the ages when the products of the US companies was manufactured in the U.S.A.

The unit is heavy. It is around 10Kg. And in addition it was packed and sealed in the way in the box like it would survive even an atomic war.

When I switched on, it started immediately. I made some measurements against my references, together with my HP multimeter.

Voltage:

It is slightly off, so it will need some calibration if I'll use as a reference as I planed.

Resistance:

It looks on spot. By the way it would be nice to use the 4-wire resistance measurement, but I should buy some proper test leads (Kelvin clips) for it.

After the testing I opened the box (This was the second time. The first time was in the office with my colleague).

I was shocked. Never ever seen such order in any equipment (specially in something what is old like this). This looks like an engineering masterpiece.

Every single board is enclosed in a separate plastic cover. Every single board's plastic cover has a foldable door on the top of it, allowing access to calibration handles:

And finally a card with cover opened:

I'm really happy, that I'm the owner of this equipment now on.

2014. október 1., szerda

Multimeterles 2. - Story of my stupidity

For today the power sourcing of my HP benchtop multimeter has been finished. Here is the finished 110V transformer:

Connected the multimeter to it. Switched on everything. Nothing.

I looked under the hood. There is a TO-3 cased 5V regulator in it.

On the output I measured a little more than 4.4V:

Because the Fluke just arrived and it is used I checked it with the Agilent also:

This is ~12% minus. Doesn't look good.

On the regulkator's input:

Less than 6V.

The regulator itself is an:

HP

1826-0536. There is a National Semiconductor logo on it. On the internet I found a cross reference what states that is a LM340AK-5.

This is a normal regulator and not an LDO. And the dropout is:

2V. Based on this the regulator's input should be at least 7V.

What is on some miracle this is not a 120V unit.

I found a service manual on the internet. My gratitude to HP/Agilent/Keysight.

On the actual website you can find correctly scanned the service manual of such an old unit.

In the service manual I found this:

And after some searching in the board also:

And what was the original setting? Of course 240V.

110V transformer removed, unit switched on, works.

If we are here, lets check some accuracy. My 5V-os reference:

Some reference resistance:

What is this reference resistor?

So I've a working bench multimeter and an unnecessary 110V transformer. It will be good when I got a real 110V something.

2014. szeptember 30., kedd

Engineer joke

A Fluke (Philips) PM3082 oscilloscope fall into my hands. It not really works.

At power on I got this error message:

If you can't read the text (none of the handles works, so I can't arrange the focus) here it is:

CAN'T COMMUNICATE WITH UFO

WRONG AI HARDWARE VERSION

NO ACKNOWLEDGE ON IIC

Funny guys.

At power on I got this error message:

If you can't read the text (none of the handles works, so I can't arrange the focus) here it is:

CAN'T COMMUNICATE WITH UFO

WRONG AI HARDWARE VERSION

NO ACKNOWLEDGE ON IIC

Funny guys.

Multimeterles

Here are already wrote, that I'm in trouble regarding multimeters. If somebody want to measure electronics correctly, unfortunately one multimeter is not enough.

It is frequently required to measure various parameters in parallel. For example if you want to measure the efficiency of a power supply (what I'm playing with this days), you need four multimeters (input and output voltage and current).

The take-of point was two multimeters. An old Metex and a Chinese crap called Maxwell what I bought a few years ago.

About the same time both of it died. The Maxwell done various things, went to the trash. The Metex stopped to measure resistance correctly (I don't want to trow it away, but I don't want to use it either).

To overcome the "multimeterles" state of mine, quickly bought an Agilent (ooops, it is Keysight now) U1232A to have at least one decent meter. On top of this I bought a Sanwa PS8a. This goes into my bag, because it is not really usable on the bench. You can't even put crocodile clips on it.

So it still leave me with one DMM.

I wanted to acquire the others cheaply. Ordered 3 (just two for myself) Uni-T UT136B. This looks like a decent one even it is Chinese. And in addition ordered a HP 3478A (used cheaply) to have a reference device.

The first package lost - I still in conversation with the seller. The second one was in the hands of the Hungarian customs and the UPS for two weeks. When it finally arrived (two weeks ago), my colleague realized this is a 120V version, so I will have some work with it before I can use it.

Finally I still have only one multimeter.

Update - yesterday I got a Fluke 117 bought cheaply on ebay.

It is frequently required to measure various parameters in parallel. For example if you want to measure the efficiency of a power supply (what I'm playing with this days), you need four multimeters (input and output voltage and current).

The take-of point was two multimeters. An old Metex and a Chinese crap called Maxwell what I bought a few years ago.

About the same time both of it died. The Maxwell done various things, went to the trash. The Metex stopped to measure resistance correctly (I don't want to trow it away, but I don't want to use it either).

To overcome the "multimeterles" state of mine, quickly bought an Agilent (ooops, it is Keysight now) U1232A to have at least one decent meter. On top of this I bought a Sanwa PS8a. This goes into my bag, because it is not really usable on the bench. You can't even put crocodile clips on it.

So it still leave me with one DMM.

I wanted to acquire the others cheaply. Ordered 3 (just two for myself) Uni-T UT136B. This looks like a decent one even it is Chinese. And in addition ordered a HP 3478A (used cheaply) to have a reference device.

The first package lost - I still in conversation with the seller. The second one was in the hands of the Hungarian customs and the UPS for two weeks. When it finally arrived (two weeks ago), my colleague realized this is a 120V version, so I will have some work with it before I can use it.

Finally I still have only one multimeter.

Update - yesterday I got a Fluke 117 bought cheaply on ebay.

2014. szeptember 29., hétfő

Kapton transfer - FAILED

Base on this article I also wanted to try out the Kapton tape instead of the paper I'm using.

The result....

Tragical:

First of all I was thinking, that the whole thing is a catastrophe and goes to the trash.

After it I was thinking over my past and realized the following:

Compared to these the Kapton based solution is not to bad even.

What I know for sure:

The result....

Tragical:

First of all I was thinking, that the whole thing is a catastrophe and goes to the trash.

After it I was thinking over my past and realized the following:

- The photo resistive process was never working to me.

- The toner transfer I'm using today started to produce acceptable result after months

Compared to these the Kapton based solution is not to bad even.

What I know for sure:

- This board will be created with the regular paper based transfer

- I don't give up this Kapton based process, I will continuously trying it.

The Little Box Challenge

After long thinking, team building, I couldn't resist. Registered.

Don't be afraid. The real work will not come from me. I'm just "managing" the team.

Don't be afraid. The real work will not come from me. I'm just "managing" the team.

2014. szeptember 19., péntek

POM #1 - Voltage inverter for breadboards 2.

After some fighting (with myself) finally ordered the PCBs.

The dritypcbs immediately create this view from the gerber what is awesome, I'm fell in love. :-)

Yes, you can see it correctly, not just the POM1 on the board. On the whole 7 PCBs on the board. 4 POM1 and 3 PCBs what allows to use various connectors on the breadboard: Stereo RCA, USB B and 3,5 mm jack.

The dritypcbs immediately create this view from the gerber what is awesome, I'm fell in love. :-)

Yes, you can see it correctly, not just the POM1 on the board. On the whole 7 PCBs on the board. 4 POM1 and 3 PCBs what allows to use various connectors on the breadboard: Stereo RCA, USB B and 3,5 mm jack.

2014. szeptember 13., szombat

POM #1 - Voltage inverter for brreadboards 1.

I was thinking a lot, how to start this series, to finish the design by end of the month for sure. Among the project in my head this is the simpliest one.

The job of this thing to invert the voltage (typically +5V) arriving to the breadboard, generating a -5V loadable with a few mA-s.

What this is good for? Frequently happening that I need analog circuitry - typically opamps - connected to my digital stuff. In addition, the single supply is not always enough for these (handling DC coupled analog input signal).

The circuit is built around the ICL7660 (LTC1044, LTC1046) and contains only two external components - two 10uF capacitors.

The design is finished. Even I tried it out.

Schematic design:

Built (On breadboard):

The picture requires some explanation. The DMM measures the voltage between incoming ~5VDC from USB and the output of the ICL7660. It would be good to show more values but unfortunately in this very moment I'm not really equipped with multimeters.

PCB design:

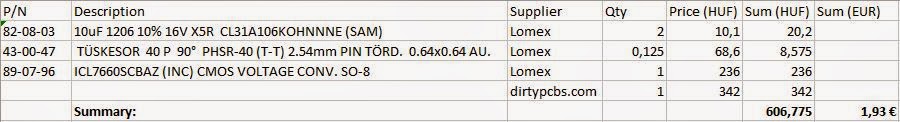

Cost structure:

The full material cost is around 2€, what doesn't look to much. In this time I'm intend to try out the Dirt Cheap PCB as manufacturer.

The job of this thing to invert the voltage (typically +5V) arriving to the breadboard, generating a -5V loadable with a few mA-s.

What this is good for? Frequently happening that I need analog circuitry - typically opamps - connected to my digital stuff. In addition, the single supply is not always enough for these (handling DC coupled analog input signal).

The circuit is built around the ICL7660 (LTC1044, LTC1046) and contains only two external components - two 10uF capacitors.

The design is finished. Even I tried it out.

Schematic design:

Built (On breadboard):

The picture requires some explanation. The DMM measures the voltage between incoming ~5VDC from USB and the output of the ICL7660. It would be good to show more values but unfortunately in this very moment I'm not really equipped with multimeters.

PCB design:

Cost structure:

The full material cost is around 2€, what doesn't look to much. In this time I'm intend to try out the Dirt Cheap PCB as manufacturer.

2014. augusztus 31., vasárnap

USB supply - teardown

I'm sure you know that small slim power supplies what you connect to the mains and it has a USB on the top. That ones, what supplied for the iPhone.

I broke one of the mains legs.

I took it apart. Not the one supplied for the iPhone but a similar one, so there is no warranty that it is the same inside.

Here it is:

That's all.

The key component is a an ATS1636 named chip. It is manufactured by the "well known" ArtChip. Thay have a website. It is located on the artchipsemi.com address. The content is: 503 Service Unavailable.

I found a datasheet also:

http://www.szzcchina.com/cn/pdf%5CCH-ATS1636-V1p1.pdf

The chip according to the datasheet - because my Chinese is sooo good :-D (google translate):

"ATS1636 is suitable for low-cost, high-precision constant current and voltage requirements

(CC / CV) applications. Constant current loop without optocouplers, TL431 and complement

Compensation circuitry integrated 700V power MOSFET, reducing system cost.

ATS1636 meet the output voltage of ± 5% production accuracy. Pole

Low starting current, accurate detection can easily meet EPA2.0 bottom

Energy efficiency requirements. Output cable voltage compensation can be based on customer

The required adjustment, greatly facilitate the customer on the system design.

ATS1636 also integrates several protection features: undervoltage lockout, the former

Edge blanking, overvoltage protection, overcurrent protection, open loop protection, lose

Short circuit protection, which greatly increases the stability of the system. ATS1636

SOP-8 package is provided, ATS1636S for SOP-7 package."

I found a schematic diagram what mostly covers the thing what I have:

http://detail.1688.com/offer/1173450146.html

I broke one of the mains legs.

I took it apart. Not the one supplied for the iPhone but a similar one, so there is no warranty that it is the same inside.

Here it is:

That's all.

The key component is a an ATS1636 named chip. It is manufactured by the "well known" ArtChip. Thay have a website. It is located on the artchipsemi.com address. The content is: 503 Service Unavailable.

I found a datasheet also:

http://www.szzcchina.com/cn/pdf%5CCH-ATS1636-V1p1.pdf

The chip according to the datasheet - because my Chinese is sooo good :-D (google translate):

"ATS1636 is suitable for low-cost, high-precision constant current and voltage requirements

(CC / CV) applications. Constant current loop without optocouplers, TL431 and complement

Compensation circuitry integrated 700V power MOSFET, reducing system cost.

ATS1636 meet the output voltage of ± 5% production accuracy. Pole

Low starting current, accurate detection can easily meet EPA2.0 bottom

Energy efficiency requirements. Output cable voltage compensation can be based on customer

The required adjustment, greatly facilitate the customer on the system design.

ATS1636 also integrates several protection features: undervoltage lockout, the former

Edge blanking, overvoltage protection, overcurrent protection, open loop protection, lose

Short circuit protection, which greatly increases the stability of the system. ATS1636

SOP-8 package is provided, ATS1636S for SOP-7 package."

I found a schematic diagram what mostly covers the thing what I have:

http://detail.1688.com/offer/1173450146.html

2014. augusztus 30., szombat

Back to work

The vacation is over. We arrived back to home. From Monday I'm going back to work, and the school is opening also.

I was thinking a lot during my vacation. Many new project ideas come into my mind, and I was thinking, how can I change on the fact, that many of my projects are waiting to be get finished. More and more projects, longer and longer.

There come the idea to announce for myself the POM (Project Of the Month). From this moment I will assign a project to every month, what will be finished in that month. Will it work? I don't know, we will see.

I want to start with simple things.

I was thinking a lot during my vacation. Many new project ideas come into my mind, and I was thinking, how can I change on the fact, that many of my projects are waiting to be get finished. More and more projects, longer and longer.

There come the idea to announce for myself the POM (Project Of the Month). From this moment I will assign a project to every month, what will be finished in that month. Will it work? I don't know, we will see.

I want to start with simple things.

2014. augusztus 14., csütörtök

Arrived

After a long waiting it is arrived. This is the first thing I backed on the Kickstarter and arrived.

Here it is:

Now the question is when will happen the first project I can use it in.

Here it is:

Now the question is when will happen the first project I can use it in.

2014. augusztus 11., hétfő

Arduino

Yet another meeting with the Arduino IDE. The subject doesn't changed. The Marlin firmware.

The IDE once more proved it's incredible usability. What if I have more files than fit on the screen?

3D Printer Marlin firmware on 1920x1200-as monitor (screenpart):

I'd like to open something! Yes, you see correctly, something there, down below!

My opinion about the Arduino Erich Styer phrased precisely here:

"Maybe it is just me: I respect the ‘Arduino way of programming’, but it is just not the way I think development should be done. I need full control of the hardware which includes deep inspection (debugging) of the application. Because in my experience the hard problems (and there are many!) of embedded development can only be solved with good debugging tools."

The IDE once more proved it's incredible usability. What if I have more files than fit on the screen?

3D Printer Marlin firmware on 1920x1200-as monitor (screenpart):

I'd like to open something! Yes, you see correctly, something there, down below!

My opinion about the Arduino Erich Styer phrased precisely here:

"Maybe it is just me: I respect the ‘Arduino way of programming’, but it is just not the way I think development should be done. I need full control of the hardware which includes deep inspection (debugging) of the application. Because in my experience the hard problems (and there are many!) of embedded development can only be solved with good debugging tools."

CNC - It is arrived!

The postman came. And he bring this:

My shiny new 400W spindle motor for the CNC.

I think, I'll put it together tonight.

My shiny new 400W spindle motor for the CNC.

I think, I'll put it together tonight.

2014. augusztus 6., szerda

Challenge

I'm interested in the photovoltaic systems for a while (I'll get it once).

A few days ago in one of the manufacturers newsletter I seen a link. The Google and the IEEE started a challenge for designing and building a high efficiency small size photovoltaic inverter:

On my own not experienced in power electronics, but if somebody interested and has knowledge can participate. The registration deadline is 2014. September 30. The first prize:

A few days ago in one of the manufacturers newsletter I seen a link. The Google and the IEEE started a challenge for designing and building a high efficiency small size photovoltaic inverter:

On my own not experienced in power electronics, but if somebody interested and has knowledge can participate. The registration deadline is 2014. September 30. The first prize:

$1.000.000

2014. július 30., szerda

The guilty

After my CNC stopped, measured a quick one, for deciding if the motor or the power supply is the guilty one.

It was the motor.

This means I've to face my largest fear regarding the CNC. The motor holder and the whole z-axis moving parts are manufactured from a single piece of metal. The motor was so tight in it that I cant remove it without much force (I tried already). I fear if I try to strain it to hard, it will broke.

Finally I was searching a wooden wedge in my workshop, removed the two screws, stave the wedge into the holder and with some force I was able to remove the motor.

Here is the guilty:

I ordered quickly a new one - this time a 400W one - from the eBay. Until it arrives I put the CNC aside. But it is possible that I tear down the motor to see what is the problem.

It was the motor.

This means I've to face my largest fear regarding the CNC. The motor holder and the whole z-axis moving parts are manufactured from a single piece of metal. The motor was so tight in it that I cant remove it without much force (I tried already). I fear if I try to strain it to hard, it will broke.

Finally I was searching a wooden wedge in my workshop, removed the two screws, stave the wedge into the holder and with some force I was able to remove the motor.

Here is the guilty:

I ordered quickly a new one - this time a 400W one - from the eBay. Until it arrives I put the CNC aside. But it is possible that I tear down the motor to see what is the problem.

2014. július 28., hétfő

SG90 servo controller

If I'm finally able to reconstruct my 3D printer (I haven't touched it for a while) I want to have an automatic bed leveler on it, because the bed leveling today is painful. I found a solution what I like: https://www.thingiverse.com/thing:301715

For this I ordered a fistful of SG90 servos from the eBay what already arrived for a while.

At the end of the last week a task come by. It should be solved to change the vertical angle of a small webcam, what is in a not easily accessible place. I had only the weekend for it because I wanted to finish until today.

The original idea was the following:

TI Launchpad + SG90 servo, connected to a PC via USB port and it can be controlled from there.

I found a small sample code on the net:

https://www.youtube.com/watch?v=b0SYQ7JHgt4

It was working, but I didn't liked it. I was trying to write something based on the datasheet. The code was not working. The timing on the datasheet had no connection to the reality.

Finally I totally rewrote what I originally found. Restructured it just kept the timing.

After this the serial communication come.

After a bit struggling become clear that the user serial function of the LanuchPad is not even close to a working thing under Windows 8.1. The driver is there. It even allows me to connect, just no communication in the terminal emulator.

I picked from my drawer a CP2102 board from the Conrad. After some driver collection, it started instantly. I finalized the code, everything works, just I can't leave the it mechanically in this shape.

Unfortunately drawing schematics, designing and manufacturing PCB was out of question, because of the time. Only the perfboardleft as option (ohh, how I hate it).

Here is the result:

I'll put the finished code out to the GitHub.

Unfortunately I was not able to finish the whole project. When I tried to mill the camera holder on the CNC the spindle stopped and didn't started anymore. For the time being I had no energy to take it apart to find out, if the spindle or the shiny new PSU is the cause. I'll measure around tomorrow morning to find it out.

For this I ordered a fistful of SG90 servos from the eBay what already arrived for a while.

At the end of the last week a task come by. It should be solved to change the vertical angle of a small webcam, what is in a not easily accessible place. I had only the weekend for it because I wanted to finish until today.

The original idea was the following:

TI Launchpad + SG90 servo, connected to a PC via USB port and it can be controlled from there.

I found a small sample code on the net:

https://www.youtube.com/watch?v=b0SYQ7JHgt4

It was working, but I didn't liked it. I was trying to write something based on the datasheet. The code was not working. The timing on the datasheet had no connection to the reality.

Finally I totally rewrote what I originally found. Restructured it just kept the timing.

After this the serial communication come.

After a bit struggling become clear that the user serial function of the LanuchPad is not even close to a working thing under Windows 8.1. The driver is there. It even allows me to connect, just no communication in the terminal emulator.

I picked from my drawer a CP2102 board from the Conrad. After some driver collection, it started instantly. I finalized the code, everything works, just I can't leave the it mechanically in this shape.

Unfortunately drawing schematics, designing and manufacturing PCB was out of question, because of the time. Only the perfboardleft as option (ohh, how I hate it).

Here is the result:

I'll put the finished code out to the GitHub.

Unfortunately I was not able to finish the whole project. When I tried to mill the camera holder on the CNC the spindle stopped and didn't started anymore. For the time being I had no energy to take it apart to find out, if the spindle or the shiny new PSU is the cause. I'll measure around tomorrow morning to find it out.

Feliratkozás:

Megjegyzések (Atom)