2015. november 11., szerda

Enough

Just three weeks left out of the two years since I continuously struggling with my 3D printer. I put it aside several times, because it creates the feeling of being unsuccessful, every time I touch it. To every successful print the way goes through at least ten unsuccessful ones and hardware tweaking. The 3D printer is not a goal, it is a tool for me.

Two days ago, I was in such a good mood that I felt, even a 3D print can be successful. I was wrong. Tried to print out some standoffs for the printer itself from PLA, to allow enough airflow to cool the badly designed electronics inside to be able to print with ABS without Marlin freezing to death (as usual).

First print failed - my fault the filament stuck outside the printer.

Second print failed - the Y axis started to jump something like this: http://community.robo3d.com/index.php?threads/shifting-layers-in-y-axis.4690/

Third print - The head picked up the whole print, and I still trying to remove the plastic from the print head.

So, it is ENOUGH!!! Not worth the effort. This is a badly designed complete crap. I think I put already much more effort into tweaking this than it worth. "Beyond economical repair" :-)

As today is the Big Chinese Online Shopping Day, I bought a decent printer from Geeetech, for a quite reasonable price (less than a half of "that crap"):

And when it arrive, "that crap" goes to Vatera (local ebay like auction portal)

2015. szeptember 16., szerda

USB Microscope "Stand"

To be honest, I'm not a great fan of Lego. While I was a child, I played with it, but not to much. I was jumping into the electronics quite early and abandoned Lego.

The years passed, and now I've a son, who is obsessed to the Lego. This frighten me a bit.

Together with the one I wrote about, I bought an other microscope also. I wanted to use this as a magnifying glass on my desk. Arrived. I realized that the stand came with it, is a heap of crap.

I wanted to have something what I can build quickly, because I've no time to build the final solution, what is in my mind.

So I borrowed some Lego parts from my son. Here is the result. The height can be adjusted, solving the focus adjustment:

In the background you can see the image it makes.

The years passed, and now I've a son, who is obsessed to the Lego. This frighten me a bit.

Together with the one I wrote about, I bought an other microscope also. I wanted to use this as a magnifying glass on my desk. Arrived. I realized that the stand came with it, is a heap of crap.

I wanted to have something what I can build quickly, because I've no time to build the final solution, what is in my mind.

So I borrowed some Lego parts from my son. Here is the result. The height can be adjusted, solving the focus adjustment:

In the background you can see the image it makes.

Ordering from China

I'm continuously ordering things from China on the eBay and AliExpress.

Now I ordered a USB LCD microscope. This one:

Arrived, but no battery included.

Ok. Lets talk with the seller (the gray italic is just my thoughts, not actually was in the letters)

Me: The item arrived without the rechargeable battery. I don't know if this is intentional or not (I'm aware that certain regulations doesn't allow the shipment of the battery). Anyways: Please tell me the exact battery model needed, and if keeping out the battery was unintentional, I'd like to get one.

Seller: Thank you for your kind email and sorry for the trouble.

Sorry to say the item does not include a battery.

Because of the aircraft accident, our shipping company

does not ship items with batteries included now.

Powered by: 3.7V-4.2V Rechargeable lithium battery

In this case, how about you buy the battery in your local place?

We will be responsible for the cost of the battery.

Do you agree?

We look forward to your reply.

Me: Thank you for the answer and your generous offer, but I still would like to know the exact type of the battery, because

"Powered by: 3.7V-4.2V Rechargeable lithium battery" is too generic to find out what kind of battery I need.

Seller: We confirm this is the exact type of the battery: 3.7V-4.2V Rechargeable lithium battery .

You can have a check on eBay.

Then you can choose one and buy it .

Any question is welcome.

Have a nice day.

Me: Yes, I can confirm, that you are a complete idiot.

Let's assume, that you haven't got a clue about, what kind of battery is needed, but you will never admit it.

So, to help you. Fortunately I had a Nokia battery, what almost fitted into the unit. Based on this battery I made some research, to find a bit shorter one. Actually I found installed and tried out.

Please be so kind, to add to the description to the unit, to help to the future buyers. The battery what fits into the unit is the Nokia BL-5B. I bought one, for nuts, so I don't need any refund.

In addition, one of the LEDs on the bottom is dead, what I not fill as a serious problem. I'll repair it instead of sending back.

As I not really like if somebody think I'm a fool, this will be the first time when I got the article I ordered and will not add a five star review.

Now I ordered a USB LCD microscope. This one:

Arrived, but no battery included.

Ok. Lets talk with the seller (the gray italic is just my thoughts, not actually was in the letters)

Me: The item arrived without the rechargeable battery. I don't know if this is intentional or not (I'm aware that certain regulations doesn't allow the shipment of the battery). Anyways: Please tell me the exact battery model needed, and if keeping out the battery was unintentional, I'd like to get one.

Seller: Thank you for your kind email and sorry for the trouble.

Sorry to say the item does not include a battery.

Because of the aircraft accident, our shipping company

does not ship items with batteries included now.

Powered by: 3.7V-4.2V Rechargeable lithium battery

In this case, how about you buy the battery in your local place?

We will be responsible for the cost of the battery.

Do you agree?

We look forward to your reply.

Me: Thank you for the answer and your generous offer, but I still would like to know the exact type of the battery, because

"Powered by: 3.7V-4.2V Rechargeable lithium battery" is too generic to find out what kind of battery I need.

Seller: We confirm this is the exact type of the battery: 3.7V-4.2V Rechargeable lithium battery .

You can have a check on eBay.

Then you can choose one and buy it .

Any question is welcome.

Have a nice day.

Me: Yes, I can confirm, that you are a complete idiot.

Let's assume, that you haven't got a clue about, what kind of battery is needed, but you will never admit it.

So, to help you. Fortunately I had a Nokia battery, what almost fitted into the unit. Based on this battery I made some research, to find a bit shorter one. Actually I found installed and tried out.

Please be so kind, to add to the description to the unit, to help to the future buyers. The battery what fits into the unit is the Nokia BL-5B. I bought one, for nuts, so I don't need any refund.

As I not really like if somebody think I'm a fool, this will be the first time when I got the article I ordered and will not add a five star review.

2015. szeptember 14., hétfő

Supermicro Server hacking - Failed

This is a hack, but not from software point of view. It is some hardware.

I wanted to put a 2.5" SSD into the Supermicro's 3.5" hot swap drive carrier:

Disassembled the carrier, and the problem can be seen right from the beginning:

All 3.5" drives has three holes on each side. In most cases the middle screw hole isn't used.

The carrier has no hole there. But the 2.5/3.5 conversion tray need that hole.

Hole missing, so drilled it:

The carrier also has spring inserts, what also need that hole. The spring is a very thin material. I tried to drill a hole into it:

Ooops, these screws are to long. I can't cut them while it is in the tray. The cutting will be way too hot for that plastic.

It took a while, to find out, how to secure these screws into the vise to cut them.

Finally succeeded.

At that point I assembled the whole thing perfectly. When I tried to find some screws to secure the SSD into the first thing I found the screws perfectly fits in the place of the recently cut ones. :@

Finally I tried to insert the carrier into the servers cage. Didn't fit in. I found out why:

FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!!

I'm a complete idiot. I hadn't checked this in the first place.

I wanted to put a 2.5" SSD into the Supermicro's 3.5" hot swap drive carrier:

Disassembled the carrier, and the problem can be seen right from the beginning:

All 3.5" drives has three holes on each side. In most cases the middle screw hole isn't used.

The carrier has no hole there. But the 2.5/3.5 conversion tray need that hole.

Hole missing, so drilled it:

The carrier also has spring inserts, what also need that hole. The spring is a very thin material. I tried to drill a hole into it:

FAIL!!!!

Ok, I still have other unused carriers, so next try. What if I mount the conversion tray before putting in the spring insert, and not drilling it at all.

Lets try:

It took a while, to find out, how to secure these screws into the vise to cut them.

Finally succeeded.

At that point I assembled the whole thing perfectly. When I tried to find some screws to secure the SSD into the first thing I found the screws perfectly fits in the place of the recently cut ones. :@

Finally I tried to insert the carrier into the servers cage. Didn't fit in. I found out why:

FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!! FAIL!!!

I'm a complete idiot. I hadn't checked this in the first place.

2015. szeptember 4., péntek

KiCAD vs. GitHub

I don't know if this is documented somewhere or not. This is my findings. I see in the current KiCAD nightly builds that it is able to use module libraries from the GitHub repo, what is kind a cool. I've a long standing problem, how to share the modules I designed between my projects and machines. It would be the solution.

As somebody almost never read any manual, created a repo in my GitHub account, added my modules to it, then I went to the KiCAD and added the repo:

The result is not really what I expected.

After some reading, and trying here are my findings. The way I was thinking above, just not works.

First of all. The structure differ from that. In the KiCAD's thinking one new style of .pretty type library is "A" repo itself, and not a repo store several libraries. In addition, the KiCAD access the repo on programmatic way, so it needs some additional configuration.

So I decided to create a new organization for it on the GitHub.

Here are the steps - Kind of picture blog style. :-)

Create a new organization:

Remove the restrictions for third party application access (necessary for the KiCAD)

Adding the modules to the repo with your usual toolset

Now you can add the organization (not the repo directly) to the KiCAD:

And here is the result:

2015. szeptember 1., kedd

TI Precision Labs - Arrived

And finally...

After some fighting with the Fedex/Customs Office, it landed on my desk:

Let the learning begin...

After some fighting with the Fedex/Customs Office, it landed on my desk:

Let the learning begin...

2015. augusztus 19., szerda

Breaking News - TI Precision Labs

Here I wrote about the Texas Instruments Precision Labs, the insane price of it and my plans to replicate it.

I even started to work on it, replicated the schematics in KiCAD, created the PCBs for the OpAmp inserts, and partially designed the main board itself.

In addition I posted this project to the Hackaday.io, and it found it's way to the Hackaday blog itself:

http://hackaday.com/2015/06/10/hackaday-prize-entry-teaching-opamps/

I don't know if somebody at TI read what I wrote, but this came today in a newsletter:

So, mine is on the way to Budapest:

I even started to work on it, replicated the schematics in KiCAD, created the PCBs for the OpAmp inserts, and partially designed the main board itself.

In addition I posted this project to the Hackaday.io, and it found it's way to the Hackaday blog itself:

http://hackaday.com/2015/06/10/hackaday-prize-entry-teaching-opamps/

I don't know if somebody at TI read what I wrote, but this came today in a newsletter:

So, mine is on the way to Budapest:

I payed ~$60 for it with shipping.

If you need it hurry up, while it lasts.

Notes:

First: The project is officially canceled - I've many more things to do

Second: Great thank you for Texas Instruments, for this offer!

2015. augusztus 13., csütörtök

CNC Motor Driver 13. - Front Panel Board

More than a week ago the boards finally arrived:

Then I soldered the parts into it:

I picked one of my Nuvoton development board, cut it to it's parts, and soldered the missing headers, to be able to use it as an ICE programmer/debugger:

Finally, I started to rewrite the controller's program, to the new pin configuration. During this process, I also want to little bit clean up the code.

To test the board is working, I wrote a "Hello World" for it. :-)

The board looks like working so far. The next step would be to finish the conversion/clean up the code.

Then I soldered the parts into it:

I picked one of my Nuvoton development board, cut it to it's parts, and soldered the missing headers, to be able to use it as an ICE programmer/debugger:

Finally, I started to rewrite the controller's program, to the new pin configuration. During this process, I also want to little bit clean up the code.

To test the board is working, I wrote a "Hello World" for it. :-)

The board looks like working so far. The next step would be to finish the conversion/clean up the code.

2015. augusztus 5., szerda

Expandable breadboard 2. - Stickvise

When I created my expandable breadboard, I got a comment from Alex Rich who is the designer of the StickVise. He told, that I should make a "breadboard jaws" for it.

I was thinking about it, even ordered some parts (longer rod for the StickVise), and finally yesterday I made it:

And I made a video about the building. This is the first one where I'm talking, so you can see my horrible english :-)

I was thinking about it, even ordered some parts (longer rod for the StickVise), and finally yesterday I made it:

And I made a video about the building. This is the first one where I'm talking, so you can see my horrible english :-)

UV Lightbox 19. - New display

As I wrote in my last entry about the Lightbox, I ordered a new display. It is arrived more than three weeks ago (I was on vacation, therefore wasn't able to write this entry).

Tested it:

It works, visible, but still dim a bit. I'll keep it until the enclosure finished. We will see, if it is good enough when it is mounted in it.

Tested it:

It works, visible, but still dim a bit. I'll keep it until the enclosure finished. We will see, if it is good enough when it is mounted in it.

2015. július 20., hétfő

CNC Motor Driver 12. - Front Panel design finished

As I promised my previous post, I made some tweaks on the front panel schematics. To be precise, connected the push button of the rotary encoder to the MCU. This gives me the flexibility to use the rotary encoder to navigate in some kind of menu system (if I write some code for it), able to eliminate the additional physical controls (mode switch, calibration switch), and provide the possibility to add more function. Here is the modification of the schematic drawing (actually I can't insert the full page here - lack of resolution of the computer where I'm writing this actually. All of the drawings can be downloaded from the github repo)

I think, the current schematic will be the final one, if I don't find any additional problems with it. So I designed the board:

And ordered it form the dirtypcbs.com

Waiting to arrive...

I think, the current schematic will be the final one, if I don't find any additional problems with it. So I designed the board:

And ordered it form the dirtypcbs.com

Waiting to arrive...

2015. július 17., péntek

UV Lightbox 18. - Display build - Success? Failure?

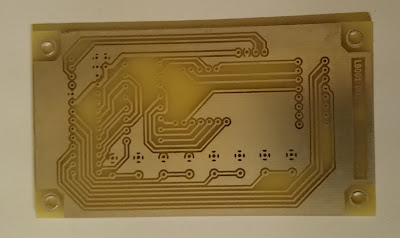

I designed...

etched...

and built a new display panel:

I wanted to do this, because I really didn't liked the original one. Too thin PCB lines what barely survived the etching (even my masking technique advanced since), the buttons are to close to each other, the display is not fitted tightly enough, the connector was in the wrong place.

I tested it. Works...

...but I can't call it a complete success. As you can('t) see the display is so dim, that it is almost invisible.

I know the reason why. It dated back in a few years. Let say five years ago, I wanted to build something. I bought a LED display and some drivers to it. The build didn't happened. To be honest I don't even remember, what was it. The LED display left in my drawer.

When I started to build this lightbox, I was thinking, that is a good idea to use the display from the drawer. It is a HDSP-B09G display from Avago (formely Agilent (formely HP)). As I figured out this is a real old design, with low intensity LEDs.

When I realized, this is a crap, I started to search something with the same pin configuration. The result is NULL - except Avago's minimally newer HDSP-B03E. I'm not confident, that this one is really brighter.

So I've two choices:

So I order the Avago display, and we will see.

etched...

and built a new display panel:

I wanted to do this, because I really didn't liked the original one. Too thin PCB lines what barely survived the etching (even my masking technique advanced since), the buttons are to close to each other, the display is not fitted tightly enough, the connector was in the wrong place.

I tested it. Works...

...but I can't call it a complete success. As you can('t) see the display is so dim, that it is almost invisible.

I know the reason why. It dated back in a few years. Let say five years ago, I wanted to build something. I bought a LED display and some drivers to it. The build didn't happened. To be honest I don't even remember, what was it. The LED display left in my drawer.

When I started to build this lightbox, I was thinking, that is a good idea to use the display from the drawer. It is a HDSP-B09G display from Avago (formely Agilent (formely HP)). As I figured out this is a real old design, with low intensity LEDs.

When I realized, this is a crap, I started to search something with the same pin configuration. The result is NULL - except Avago's minimally newer HDSP-B03E. I'm not confident, that this one is really brighter.

So I've two choices:

- Try to buy and use the "brighter" Avago

- Redesign the display once more, and create a new board (Nooooooooooooo!!!!!)

So I order the Avago display, and we will see.

2015. július 8., szerda

UV Lightbox 17. - Restarting the project

This project was put on the side for a year now. Mostly because of the following factors:

About the glass/plexy:

The problem I had with it, what kind of glass/plexy/etc. should I use on the top of the LEDs to be able to allow the UV light to go through it. Even I scored a UV integrator on the eBay (for ~$20) to be able to measure the performance of the LEDs through the chosen material.

Around two month ago an idea pop into my mind that I was thinking in the wrong way all the time.

What if I turn the whole thing upside down?

Now the next step is designing and building a new enclosure. Even I went further with the thinking. I put the whole thing into a flat closed box (without an lid what can be opened) and add a drawer for the work piece. This way it occupies less space, because I can put things on the top of it.

Than I designed a new enclosure:

I've turned the lighting boards from the bottom to the top, added two drawers. The upper one keep the board during the processing, the lower one is just a drawer for copper clad boards - I'll store them there.

Now I have to disassemble this design into its components to be able to manufacture. The question what I can't answer right now, if I'll cut the pieces myself, or order it somewhere.

- Haven't found a good solution for the cover and the top glass/plexy

- Needed to create the inserts for the back panel and as the CNC died, my intention to do it, died with it

- I didn't liked the result of the woodwork

About the glass/plexy:

The problem I had with it, what kind of glass/plexy/etc. should I use on the top of the LEDs to be able to allow the UV light to go through it. Even I scored a UV integrator on the eBay (for ~$20) to be able to measure the performance of the LEDs through the chosen material.

Around two month ago an idea pop into my mind that I was thinking in the wrong way all the time.

What if I turn the whole thing upside down?

- I don't need any material between the LEDs and the mask.

- When I put the mask on to the work piece I can see the alignment, not just guess it.

Now the next step is designing and building a new enclosure. Even I went further with the thinking. I put the whole thing into a flat closed box (without an lid what can be opened) and add a drawer for the work piece. This way it occupies less space, because I can put things on the top of it.

Than I designed a new enclosure:

Now I have to disassemble this design into its components to be able to manufacture. The question what I can't answer right now, if I'll cut the pieces myself, or order it somewhere.

2015. július 7., kedd

Tons of prizes

There was a new round at Hackaday.io. This time it was based on the sponsor components used. All of the semiconductor manufacturer sponsors - namely Texas Instruments, Freescale, Microchip and Atmel had a list. 50 projects from each list (altogether 200 prizes) was awarded.

As my lucky days continues, I won the following:

A Stickvise (this is my third one):

Two Bluefruit LEs:

A Mooshimeter:

A Cordwood puzzle:

And a TV-B-Gone Kit:

I still encourage you. Post your projects! Many stuff is still waiting in the following rounds.

As my lucky days continues, I won the following:

A Stickvise (this is my third one):

Two Bluefruit LEs:

A Mooshimeter:

A Cordwood puzzle:

And a TV-B-Gone Kit:

I still encourage you. Post your projects! Many stuff is still waiting in the following rounds.

2015. július 2., csütörtök

USB Booster 1. - Faliure no 2.

It was a while I wrote about this project. Here I'd like to summarize what happened.

First Design - Fail

I designed and built a circuit based on the MCP1642:

Unfortunately some of the components not really fitted in, so some tweaking/parts changing was necessary. With some load it not really looked working, finally I realized the cause:

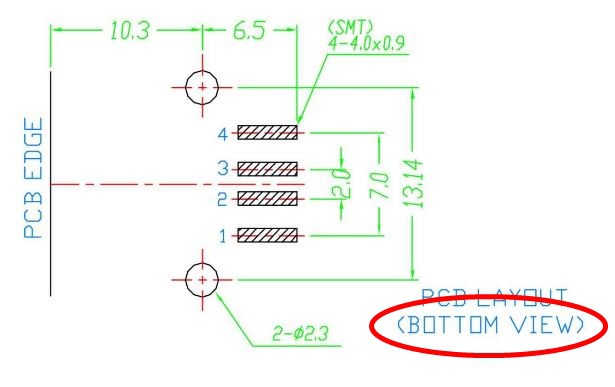

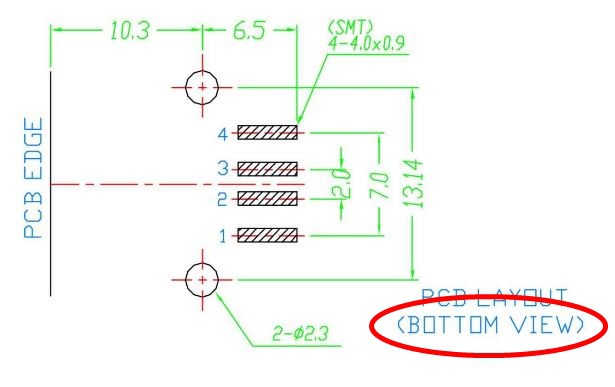

My mistake, component manufacturers insanity (my opinion).

I was not even dream of, that somebody put a PCB layout of a surface mount component from bottom view. When I created the Kicad module from the datasheet, I didn't checked this "BOTTOM VIEW" note on it. So the component was connected in the wrong direction.

So the regulator works, just the whole board useless.

PCB rediesign, rebuild...

Second Design - Fail

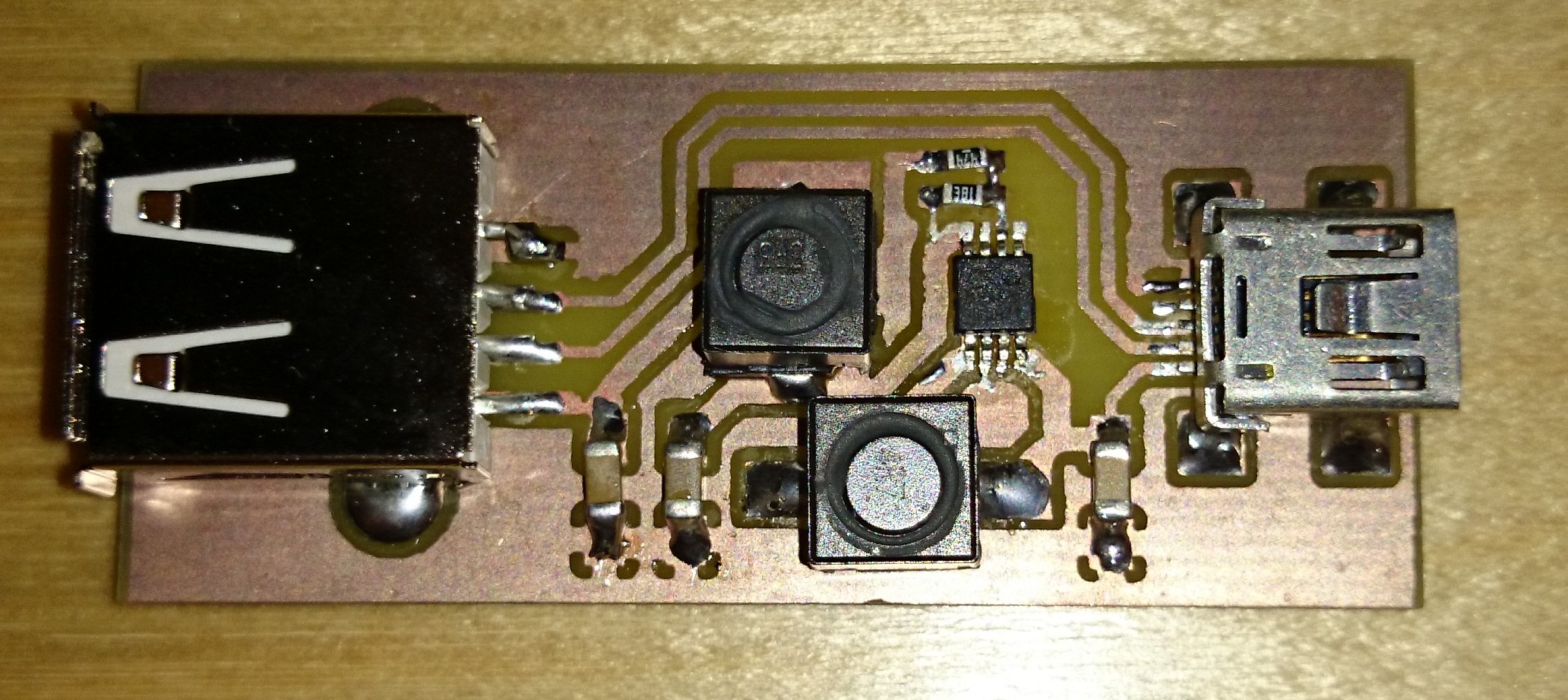

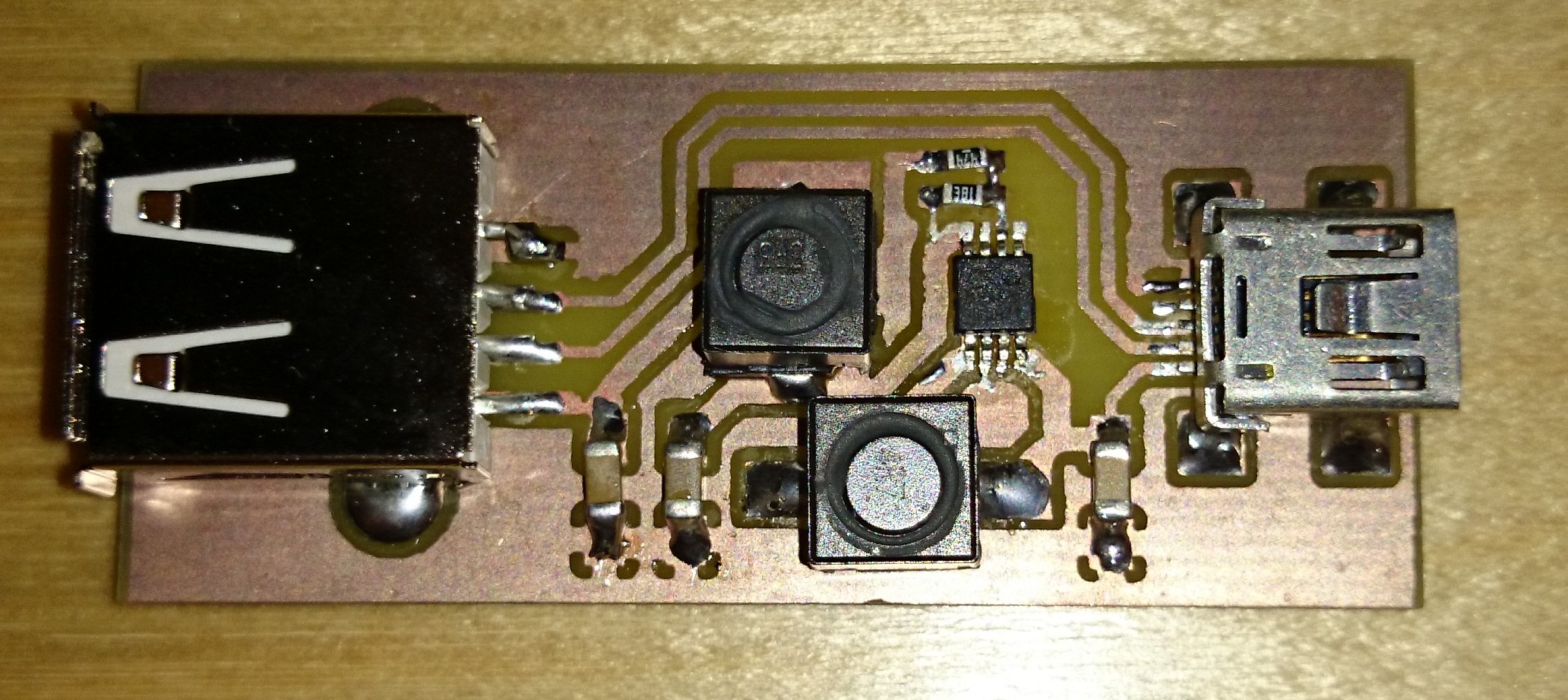

Created a second board, now with the corrected USB connector pinout:

The problems started here.

The first thing, I wanted to test it. To test it it is not enough to connect it to some random USB source. I wanted a variable source.

I've a lab supply, but it has no USB out. As I didn't wanted to cut any USB cables, I designed and built this small "tool":

After this the testing went to a complete disaster.

1. It was working from ~2V to 4.3V correctly, but when I went above 4.3V the output voltage just went above 5V. I was thinking this can be the result of miss of the minimal load, what usually required. So I setup the circuit with some (~50mA) load:

Testing..

At 2.0V:

Looks good

At 4.3V:

Still looks good

At 4.4V:

Not so good anymore. :-(

In addition, if I change the voltage, sometimes the whole circuit gets unstable. So the result clearly useless.

I've possible explanations to the things above:

- I've a crap layout - I'll try to enhance it in the next version

- I've some sort circuit(-is) things in my build. I can admit that using solid groundplane around the surface mount inductors without insulating solder mask wasn't my best idea

- The boost regulator is unable to handle the >4.3V in 5V out situation even if the datasheet just said Vout>Vin as a requirement

Here are the possible solution for the next try:

- Create a new board, with different layout and definitely with a cutout in the groundplane around the inductors

- Use the pass trough capability of the chip (this will require some kind of external comparator)

- Use a different (buck-boost or SEPIC) circuit - I may try the LM2621 what I ordered already for one of my other projects

- Keep the current boost converter (rising the output voltage to - let say - 6 volts) and use it as a pre-regulator for an LDO.

First Design - Fail

I designed and built a circuit based on the MCP1642:

Unfortunately some of the components not really fitted in, so some tweaking/parts changing was necessary. With some load it not really looked working, finally I realized the cause:

My mistake, component manufacturers insanity (my opinion).

I was not even dream of, that somebody put a PCB layout of a surface mount component from bottom view. When I created the Kicad module from the datasheet, I didn't checked this "BOTTOM VIEW" note on it. So the component was connected in the wrong direction.

So the regulator works, just the whole board useless.

PCB rediesign, rebuild...

Second Design - Fail

Created a second board, now with the corrected USB connector pinout:

And I built it:

The first thing, I wanted to test it. To test it it is not enough to connect it to some random USB source. I wanted a variable source.

I've a lab supply, but it has no USB out. As I didn't wanted to cut any USB cables, I designed and built this small "tool":

1. It was working from ~2V to 4.3V correctly, but when I went above 4.3V the output voltage just went above 5V. I was thinking this can be the result of miss of the minimal load, what usually required. So I setup the circuit with some (~50mA) load:

Testing..

At 2.0V:

Looks good

At 4.3V:

Still looks good

At 4.4V:

Not so good anymore. :-(

In addition, if I change the voltage, sometimes the whole circuit gets unstable. So the result clearly useless.

I've possible explanations to the things above:

- I've a crap layout - I'll try to enhance it in the next version

- I've some sort circuit(-is) things in my build. I can admit that using solid groundplane around the surface mount inductors without insulating solder mask wasn't my best idea

- The boost regulator is unable to handle the >4.3V in 5V out situation even if the datasheet just said Vout>Vin as a requirement

Here are the possible solution for the next try:

- Create a new board, with different layout and definitely with a cutout in the groundplane around the inductors

- Use the pass trough capability of the chip (this will require some kind of external comparator)

- Use a different (buck-boost or SEPIC) circuit - I may try the LM2621 what I ordered already for one of my other projects

- Keep the current boost converter (rising the output voltage to - let say - 6 volts) and use it as a pre-regulator for an LDO.

Feliratkozás:

Megjegyzések (Atom)